What is a Terminal Box?

Terminal box, also called “wiring center, junction box or control panel” used in air conditioning and HVAC systems, is an equipment used to connect automation components (thermostat, actuator, pump, valve, etc.) at a central point and control them in an organized manner. It ensures that electrical connections are made in an organized and safe manner.

With Terminal Box:

Different room thermostats,

- Actuators for each room (heating/cooling valves on the manifold ),

- Circulation pump,

- Boiler or heating/cooling sources are coordinated both electrically and logically via a single control panel.

What Does a Therminal Box Do?

Simplifies complex wiring.

→ Instead of running separate wires for each thermostat and actuator, all connections are made via terminal box.

Provides centralized control.

→ The status of all heating/cooling zones can be monitored here.

Integration of pump/boiler control.

→ The pump or boiler can be triggered according to requests from the thermostats. For example, if a room requests heat, the terminal box starts the pump and boiler.

Power distribution.

→ All connected devices (e.g. 230V actuators) can be supplied.

Application Areas of Terminal Box

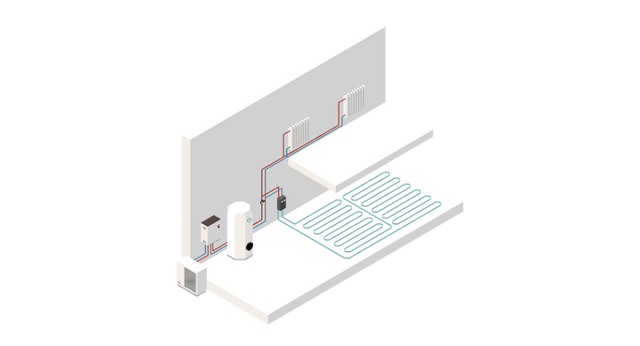

- Underfloor heating systems (residential, villa, office)

- HVAC systems

- Building automation systems

- Smart home applications

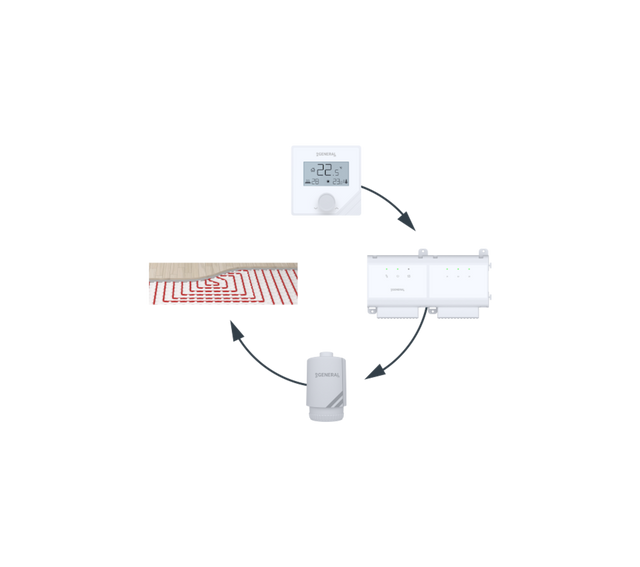

Terminal Box Operation Logic

- The room thermostat requests heating because the temperature is low.

- The Terminal Box receives this request and opens the relevant actuator.

- At the same time, it triggers the pump and boiler as there is a need for heat in the system.

- When the room temperature reaches the desired value, the thermostat stops the demand → the terminal box closes the actuator and, if necessary, stops the pump.

Multiple Zone Control

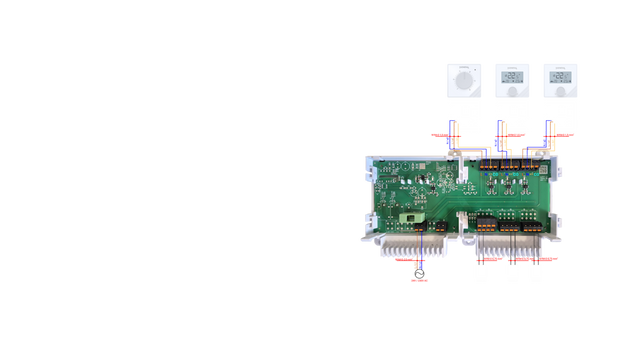

Provides independent control up to 3, 6, 9 or 12 separate zones.Separate thermostat and actuator connections can be made for each zone. Thus, special temperature control for each room becomes possible.

Energy saving and comfort are offered to the user together.

Strong and Safe Electrical Infrastructure

Compatible with different systems with 24V AC or 230V AC input voltage options.System components are fed directly from the Terminal Box. No external supply is required.Fuse protection provides safety against short circuit and overload conditions inside the device.

Grounding terminal and dry contact relay outputs (COM-NO), provide safe integration with devices that require high current, especially pump and boiler control.

Automatic Switching Between Heating and Cooling Modes

The device is suitable for both heating and cooling systems.

Switching signals between the two modes are transmitted to the connected thermostats to synchronize the system modes.

This feature provides great benefit in terms of energy optimization, especially in buildings operating in 4 seasons.

Pomp and Boiler Control

There is a periodic start-up feature at the pump outlet: It is operated for 1 minute every 14 days. This feature prevents jams and malfunctions that may occur in the pump.

The boiler control output allows the system to make safer and smoother transitions with a 4 minute delay during start and stop.

Pomp and Boiler Control

There is a periodic start-up feature at the pump outlet: It is operated for 1 minute every 14 days. This feature prevents jams and malfunctions that may occur in the pump.

The boiler control output allows the system to make safer and smoother transitions with a 4 minute delay during start and stop.

Different Product Options (ECO/COMFORT)

ECO Series: Includes thermostat and actuator connection.

COMFORT Series: Includes thermostat, actuator, boiler and pump connections.

Both series are offered with 3, 6, 9, 12 zone options.

What are the Advantages of Terminal Box’ın?

Note: If the room thermostat has a change-over output, the terminal box is designed to support this connection.

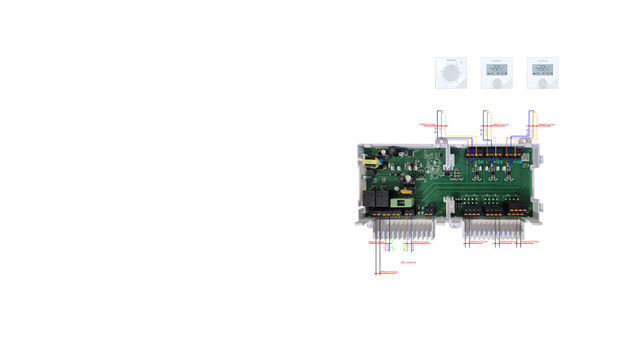

Terminal Box Eco Wiring Diagram

Note: If the room thermostat has a change-over output, the terminal box is designed to support this connection.

Terminal Box Eco Wiring Diagram